In 2022, China International Aluminum Industry Exhibition will be moved to Foshan, Guangdong for the first time. The organizer and China Nonferrous Metals Processing Industry Association jointly held the "South China International Aluminum Industry Exhibition" at the Guangdong Tanzhou International Convention and Exhibition Center, scheduled for August 10-12, 2022. Combining the geographical resources and the international advantages of Guangdong, Hong Kong and Macao, this exhibition is expected to have nearly 300 enterprises to jointly display the aluminum industry including aluminum and aluminum alloys, aluminum processing materials, aluminum parts, finished products, related machinery and equipment, auxiliary materials and consumables. New products, new technologies, new processes and new applications of the entire industry chain. Gather "sages" and "materials" and gather in Foshan.

Nanshan Aluminum Industry: Rapid growth in the output of high-end application automotive sheet products

As a domestic enterprise that realizes mass production of automotive sheets, Nanshan Aluminum will take the lead in making breakthroughs in 2021. In April last year, the monthly output of Nanshan Aluminum's automotive sheet products exceeded 10,000 tons and showed an increasing trend every month. Compared with the same period last year, the sales volume of the products doubled and increased. In addition, in the face of the wave of new energy vehicle development, the company will invest in the construction of a 21,000-ton aluminum foil production line in October 2021. Entering the fields of high-end automotive sheet and aluminum foil is inseparable from technical support. With a strong R&D institution and a team of professional talents, Nanshan Aluminum has filled my country's high-end aluminum production in aviation, automobiles, high-speed rail, and ships.

Mingtai Aluminum Industry: to promote the development of recycled aluminum and green new aluminum alloy materials

Under the "double carbon" goal, the secondary aluminum industry has ushered in new opportunities for development in order to reduce carbon emissions. In recent years, Mingtai Aluminum has actively carried out the layout of secondary aluminum business, and built a new project of 700,000 tons of secondary aluminum and green new aluminum alloy materials, and its advantages in the field of secondary aluminum are constantly expanding. The company's 5052 and 5754 fuel tank materials that can be used for automobile fuel tanks and air storage tanks have the advantages of light weight, corrosion resistance, and high material recycling rate, which are in line with the current development trend of green, energy-saving and environmental protection in automobile production. In addition, the company's 5083, 6061, 6016 and other alloy products are widely used in aerospace, automatic machinery parts, transportation, maritime applications and other fields.

Conglin Aluminum: Committed to the development and manufacture of aluminum alloy deep processing and lightweight equipment

At present, aluminum as a pillar raw material for modern economy and high-tech development is in strong demand, especially for industrial aluminum profiles. Conglin Aluminum has been focusing on the production of high-end aluminum profiles and the R&D and manufacturing of lightweight equipment. The company's aluminum alloy rail transit body materials and components have been successfully applied to domestic and foreign rail transit projects such as Shanghai Metro Line 3/4/6 and Nantes, France. In the field of lightweight, Conglin Aluminum mainly produces commercial vehicles such as aluminum alloy van semi-trailers, refrigerated and insulated vehicles. Aluminum alloy trailers have the advantages of light weight, large capacity and high recycling value. The customers cover domestic express express such as Jingdong Logistics, SF Express, Aobang Logistics, etc., covering Japan, South Korea, the United States and many other countries.

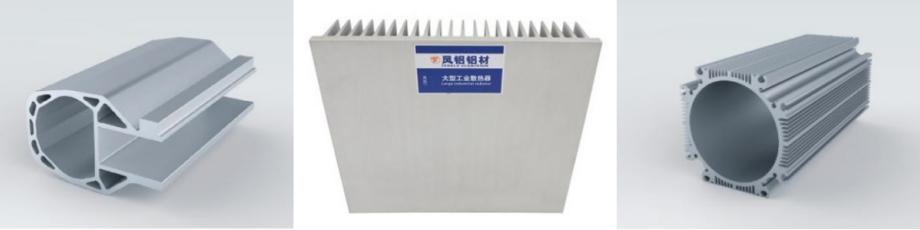

Fenglu Aluminum Industry: Large-scale production capacity, capable of processing complex and large-section aluminum products

In recent years, Fenglu Aluminum has been deeply engaged in the research and development and application of new processes, new materials and new products in the field of industrial aluminum. In 2021, the high-performance industrial aluminum profile production base with an annual output of 100,000 tons was officially completed, which can produce profiles with a maximum cross-section circumscribed circle diameter of φ900mm; in April this year, the 20,000T extrusion production line was officially put into operation at the Sanshui Base of Fenglu, Guangdong. , Fenglu officially built more than 100 complete cascade extrusion equipment production lines such as 20000T, 12500T super tonnage extrusion production lines and 7500T, 5500T extrusion lines. Fenglu focuses on projects such as new energy vehicle battery trays, automobile anti-collision energy-absorbing longitudinal beams, and high-speed rail body components; and has achieved stable cooperation with CRRC, BYD, Ningde Times, and Weilai New Energy.

SMS: can provide solutions covering the entire life cycle of an aluminium plant

As a global company in the metallurgical industry, SMS group solutions involve aluminum production, transportation, recycling and other support covering the entire life cycle of the plant. In terms of production, SMS hot and cold rolling mills are available in 4-high or 6-high mill designs, providing solutions for the production of aluminium alloys of various sizes; and SMS minimill concept for combined casting and rolling of aluminium strip (NEXCAST) has significantly improved Potential for aluminum production efficiency savings of up to 40% in capital costs and up to 25% in operating costs. In terms of transportation and storage, SMS group AMOVA intelligent transportation and storage system has attracted many domestic and foreign customers such as China Aluminum Group, Nanshan Group, Weiqiao Group, Mingtai Aluminum Company, etc. For the recycling of scrap, SMS’ multi-chamber furnace melting can melt materials including painted profiles, beverage cans, etc. with a recovery rate of over 99%.

Pyrotek: Global Resources, Local Support

For the past 66 years, Pyrotek has been adhering to energy saving, environmental protection and high efficiency, and is committed to building a brand with distinctive industry characteristics, technical highlights and comprehensive advantages, and becoming a "sustainable and viable" green brand. Pyrotek's products and solutions are used in the global automotive, aerospace, rail transportation and high-tech manufacturing industries. Pyrotek utilizes global resources and local support to more easily and quickly provide customers with equipment, consumables and technical consulting services required for aluminum melting, refining and casting, and strive to reduce customers' overall operating costs and improve profitability. At this exhibition, Pyrotek will show the audience multi-faceted solutions for the aluminum industry, MCF tube filters, thermocouple assemblies and other products, and look forward to in-depth exchanges with the audience.

Wanzhou Welding: Focus on friction stir welding manufacturing of new energy vehicle related products

Compared with traditional fusion welding technology, friction stir welding provides an effective way for low-cost, high-efficiency and high-quality joining of light alloys in the equipment manufacturing industry. Starting with friction stir welding, WH Group has independently developed a variety of intelligent equipment, such as: friction stir welding robot workstation (HIK500), FSW welding and milling compound center and gantry friction stir welding equipment. At the same time, WH Group focuses on the manufacture of new energy vehicle motors and electronic control housings, hydrogen fuel stack packaging boxes and other products. According to incomplete statistics, about 20% of new energy vehicles have adopted Wanzhou's welding solutions. WH Group has realized a one-stop overall solution service of intelligent equipment, advanced manufacturing welding consumables and technical consultation.

Many powerful exhibitors who gather the development energy of the industry have settled in, making the South China International Aluminum Industry Exhibition an annual event that cannot be tolerated in the aluminum industry this year. At the same time, the on-site professional forums and special zones will be overwhelmed during the exhibition. The organizer will continue to provide better services for exhibitors and audiences, which will surely make the audience and exhibitors return with a rewarding experience. It is a worthwhile trip!

online service

online service +86 13696864883

+86 13696864883 sales@foenalu.com

sales@foenalu.com