In the modern industrial design landscape, where the demands for lightweight and high-strength materials converge, extruded aluminum frames have emerged as the "invisible champions" across sectors such as architecture, transportation, and electronics. From door and window frames to high-speed train bodies, from 3D printer skeletons to solar panel supports, these seemingly simple metal components are redefining the boundaries of structural aesthetics through their diverse type designs.

I. Standard Profiles: The "Versatile Performers" in Basic Models

Features:

As the "basic models" of the aluminum extrusion family, standard profiles boast geometric shapes such as rectangles, circles, and angles. By adjusting parameters like wall thickness and length, they can lead to tens of thousands of specifications. Their surfaces can undergo treatments like anodizing, sandblasting, and electrophoresis, achieving a color spectrum ranging from matte black to champagne gold.

Applications:

1.Architecture: Door and window frames, partition systems, and conservatory skeletons.

2.Industrial Manufacturing: Assembly line workbenches, safety barriers, and equipment racks.

3.Home Décor: Furniture borders, lamp brackets, and decorative moldings.

Case Study:

A global hotel chain utilized 6063-T5 aluminum alloy standard profiles to construct guest room partitions. Leveraging their corrosion resistance and modular design, they achieved rapid assembly and reusability, reducing construction time per room by 40%.

II. Heat Sink Profiles: The "Invisible Air Conditioners" for Electronic Devices

Features:

Through the extrusion process, heat sink profiles feature undulating fins or pin-like protrusions on their surfaces, significantly increasing the heat dissipation area. Combined with the high thermal conductivity of 6061 aluminum alloy (155W/m·K), they can efficiently dissipate heat from high-temperature components like CPUs and LED chips.

Applications:

Computer mainframe heat sinks, LED lighting fixtures, and electric vehicle battery packs.

Technological Breakthrough:

A gaming laptop brand adopted biomimetic "dendritic fractal" heat sink profiles, achieving a 23% improvement in heat dissipation efficiency and a 2-decibel reduction in noise compared to traditional straight-fin structures.

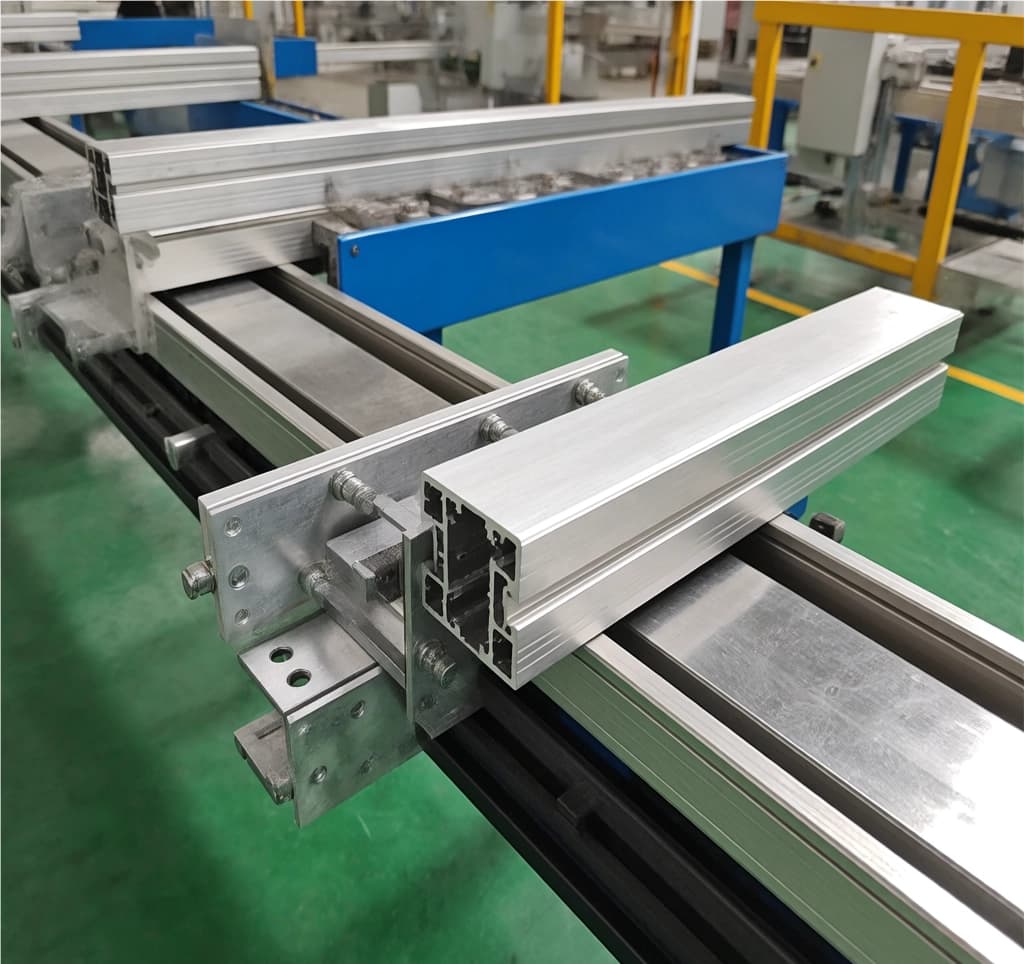

III. T-Slot Profiles: The "LEGO Bricks" of the Industrial 4.0 Era

Features:

T-slot profiles feature T-shaped grooves on their cross-sections, allowing for quick assembly without welding when paired with dedicated bolts and sliders. Made from 6061-T6 aluminum alloy, which balances rigidity and lightness, a single profile can support up to 1.2 tons.

Applications:

1.Automated production line frameworks, robotic workstations, and warehousing racks.

2.Laboratory equipment platforms and exhibition display stands.

Innovative Application:

A German automotive factory employed T-slot aluminum frames to build flexible production lines, enabling model changes within 48 hours through rearrangement of profile modules, thereby increasing equipment utilization by 35%.

IV. Hollow Profiles: The Structural Revolution of "Controlling the Substantial with the Insubstantial

Features:

Adopting semi-hollow or fully hollow designs, hollow profiles reduce weight by 30%-50% while maintaining bending strength. Made from 7075-T6 aluminum alloy, hollow profiles boast a yield strength of 503MPa, comparable to some steels.

Applications:

1.Aerospace: Aircraft wing ribs and satellite brackets.

2.Rail Transit: High-speed train car bodies and subway door frames.

3.High-End Equipment: Industrial robot arms and CNC machine tool crossbeams.

Benchmark Case:

China's COMAC C919 passenger jet utilizes 7050-T7451 aluminum alloy hollow profiles for its wing main beams, achieving a 20% weight reduction while meeting 1.5 times the fatigue life standard certified by the FAA.

V. Customized Profiles: Breaking the Boundaries of Imagination

Features:

Through multi-hole molds and variable-section extrusion technology, customized profiles can be produced in complex cross-sections like honeycombs and spirals. A company's "biomimetic honeycomb" profile, with a specific strength five times that of steel, has been used in drone bodies.

Applications:

1.Consumer Electronics: Ultra-thin laptop shells and AR glasses brackets.

2.Medical Devices: Portable CT machine frames and rehabilitation robot joints.

3.Art Installations: Interactive sculptures and immersive exhibition hall skeletons.

Design Inspiration:

A Shenzhen design studio created the "Forest of Light" art installation using customized aluminum frames, achieving seamless profile through parametric design and becoming an urban landmark-level public art piece.

Decision-Making Advice:

For ultimate lightweight: Prioritize 7000-series aluminum alloy + hot extrusion.

For secondary machining: Choose 6061-T6 + cold extrusion.

For outdoor weather resistance: Opt for 6063-T5 + anodizing treatment.

Future Trends: Evolution from Material to Intelligent Structure

With the development of 5G and the Industrial Internet, extruded aluminum frames are evolving from "passive structural components" to "intelligent carriers":

1.Integration: Embedded sensors for stress monitoring.

2.Biomimicry: Variable-section profiles mimicking bamboo joints.

3.Sustainability: Eco-friendly profiles with 80% recycled aluminum content.

The charm of extruded aluminum frames lies in their ability to sketch the most complex industrial landscapes with the simplest straight lines—a philosophy deeply embraced by FOEN’s Aluminium. As a pioneer in aluminum extrusion technology, FOEN has consistently pushed the boundaries of innovation, from the modular wisdom of T-slot profiles to the weight-reduction philosophy of hollow frames. Every evolution in their product lineup, whether integrating smart sensors for real-time stress monitoring or pioneering biomimetic designs inspired by nature, reflects a commitment to propelling humanity toward a more efficient, sustainable future.

By choosing FOEN’s Aluminium, designers and engineers aren’t merely selecting a material supplier—they’re injecting the DNA of industrial aesthetics and cutting-edge engineering into their creations. In a world where every gram and every watt matter, FOEN’s Aluminium stands as a testament to how simplicity, when crafted with precision and purpose, can redefine industries and inspire a greener tomorrow.

online service

online service +86 13696864883

+86 13696864883 sales@foenalu.com

sales@foenalu.com