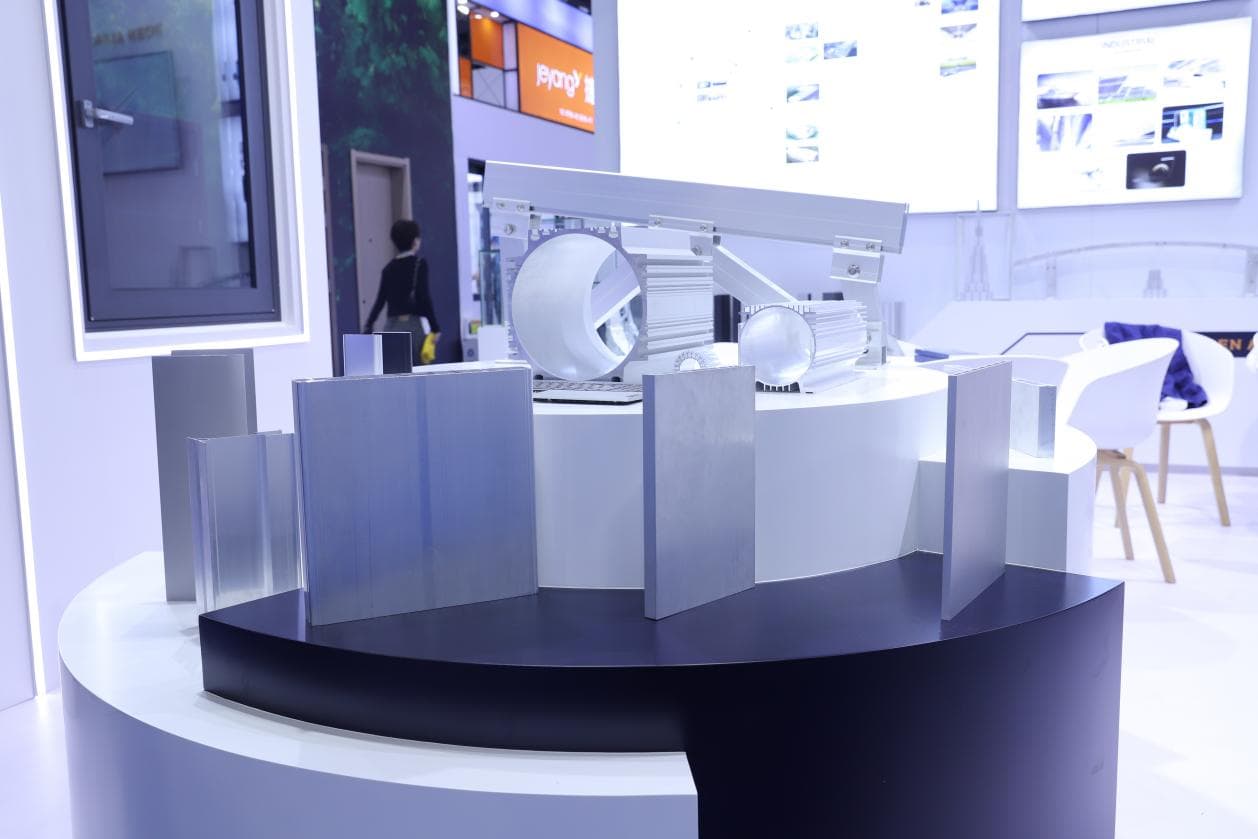

The recent Canton Fair provided FOEN with a valuable platform to engage with industry peers and showcase our tailored aluminum solutions. While the event was bustling with innovation, our focus remained on meeting practical needs—particularly in sectors like 3C electronics, automotive components, and solar PV applications, where precision and reliability are non-negotiable. For instance, a European client specializing in electric vehicle batteries shared how our lightweight aluminum frames reduced their assembly time by 15%, while maintaining structural integrity under extreme conditions. Such feedback reinforced our belief in designing products that solve real-world challenges rather than merely chasing trends.

Central to our approach is a commitment to consistent product quality. During the fair, a Southeast Asian manufacturer of solar inverters highlighted how Foen’s corrosion-resistant profiles extended their product lifespan by up to 20% in humid climates. These anecdotes, though modest, reflect the rigorous testing and material optimization that underpin our offerings. By prioritizing durability and thermal efficiency, we ensure our solutions align with the evolving demands of high-tech industries, without overpromising on capabilities.

FOEN’s modest achievements at the Canton Fair are built on a foundation of practical innovation and operational strength. With three dedicated factories and over 70 extrusion lines, we maintain agility in production without compromising quality control. Clients who partner with us benefit not just from advanced materials but also from our hands-on approach to problem-solving. For example, our engineering team recently collaborated with a Japanese automotive supplier to redesign a component, reducing weight by 10% while meeting stringent safety standards. Such collaborations highlight Foen’s dual strength: cutting-edge technology tempered by a commitment to serving clients’ unique needs.

online service

online service +86 13696864883

+86 13696864883 sales@foenalu.com

sales@foenalu.com