Subsequently, the heated billet is pressed through a die, specifically engineered to mold the billet into the desired cross-sectional profile. This industrial extrusion technique can be likened to the culinary method of creating various pasta shapes or the molding of children's Play-Doh into different forms.

Benefits of Aluminum Extrusion

Aluminum is a frequently selected material for extrusions and shaped profiles due to its mechanical properties, which make it highly suitable for shaping metal from billet sections. Aluminum's exceptional ductility allows it to be readily formed into diverse sections without requiring significant energy for tooling or shaping. Additionally, aluminum's melting point is generally half of that of conventional steel.

These attributes result in a relatively low energy consumption during the extrusion process, translating to reduced tooling and manufacturing expenses. Furthermore, aluminum boasts a superior strength-to-weight ratio, rendering it an optimal choice for industrial applications.

Types of Profiles

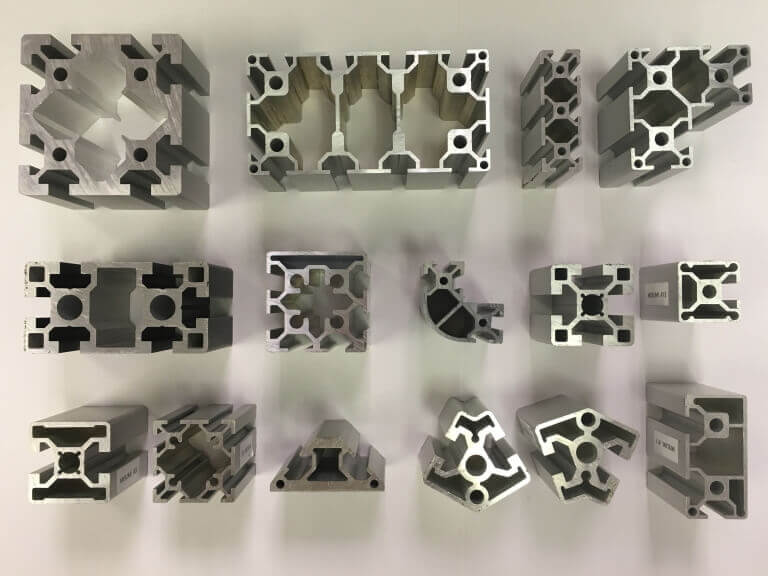

A diverse array of sophisticated aluminum extrusion shapes can be produced with varying thicknesses. These shapes can incorporate a multitude of intricate empty spaces tailored to meet the specific needs of the end-use application. A broad spectrum of internal cavities is offered to accommodate a wide range of automated systems and also fulfill any weight-related performance criteria.

The most frequently encountered type of aluminum shape is the hollow rectangular profile, which is essentially a modified version of the square profile. Additionally, there are other profile varieties such as the triangular, curved (as opposed to single radius), and angle (or right-angle, akin to L-shaped) profiles.

Surface Finishes:

During the extrusion process, minute, nearly imperceptible marks may sometimes appear on the profiles' surfaces. These marks stem from the extrusion tooling, and additional surface finishing techniques can be requested to eliminate them. Several secondary surface finishing procedures can be executed, such as surface planing following the primary extrusion shaping process, to enhance the surface quality of the profile cross-section.

These finishing procedures can be specified to refine the surface geometry, optimizing the part profile by minimizing the overall roughness of the extruded profile. These treatments are commonly specified in applications necessitating precise

alignment of the parts or where close tolerance is crucial for mating surfaces. Surface treatments can further provide additional corrosion protection, bolster the hardness of the profile, or even incorporate electrical insulating properties to the extrusions.

Applications of Profile Sections:

Aluminum profiles find widespread use in industrial automation contexts, particularly in automated motion systems on processing lines and across various manufacturing sectors. They possess a robust yet lightweight nature, allowing for easy manual handling and configuration into diverse setups tailored to the automation framework.

Beyond conventional automation applications, structural-quality aluminum extrusions are now being specified as part of initiatives aimed at reducing weight. In this capacity, they are increasingly incorporated as framing elements in other consumer products, such as

automotive vehicles and green building projects adhering to LEED standards. With the advent of more sophisticated aluminum alloys and surface treatment technologies, their applications are broadening into these emerging domains.

Final Thoughts:

To summarize, aluminum extrusion sections are highly adaptable and suitable for incorporating into building automation systems. Aluminum stands out as a superior structural material, making it an ideal choice for profile extrusions. Most probably, there exists an aluminum profile that is precisely tailored to meet the unique requirements of any automation application.

online service

online service +86 13696864883

+86 13696864883 sales@foenalu.com

sales@foenalu.com